Product Description

Fiber laser welding system and advantage

Welding with fiber lasers from HS LASER delivers superior advantages as compared with conventional joining methods. Laser welding is a non-contact process with no equipment wear or consumable usage and delivers very little heat input resulting in minimal heat affected zones and part distortion. Laser welding is the most reliable solution for high-speed, high-quality joining across a wide range of material combinations and thicknesses in nearly every industry. HS LASER fiber laser innovations coupled with the expert automated welding solutions from China best brand system are on the forefront of improving the quality, speed and flexibility for welding applications while reducing overall costs.

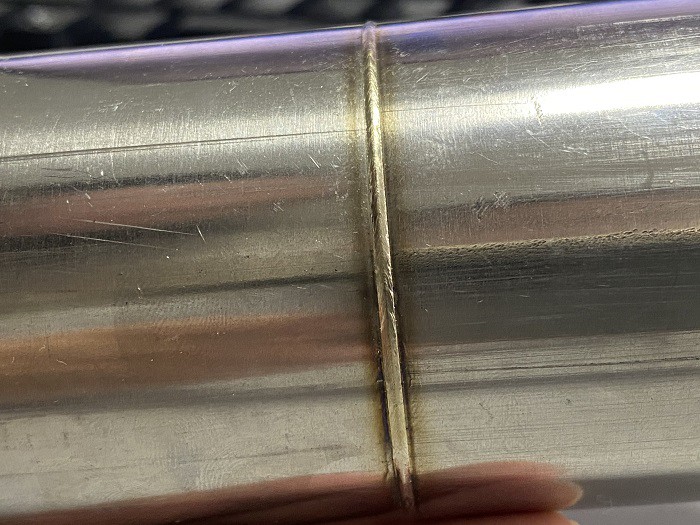

Wobble weld head advantage

Wobble weld head can be adjusted laser beam width, frequency and wobble modes. In addition to the wobble modes, both wobble frequency and amplitude can be adjusted for process optimization.

The wobble welding head has a laser integration function to assist in improving the laser energy conversion rate. Wobble welding heads are designed to provide the

highest laser power handling capability in the industry in a completely sealed and lightweight package. These process heads provide effortless integration with HS lasers

and offers improved weld quality and better visual finish. Available in multiple configurations with the broadest focus and collimator lens options, the Wobblersare the ultimate tool to weld a multitude of different material types and thicknesses.

Industry Application

Automobile manufacturing industry

Lithium battery industry

Pillow plate head exchanger

Machinery Manufacturing Industry

Furniture industry

Sheet metal processing industry

Electronic communication industrys

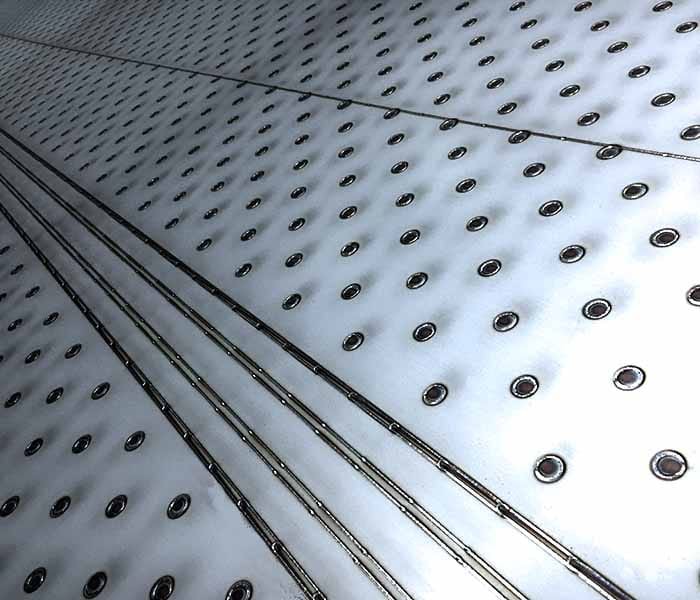

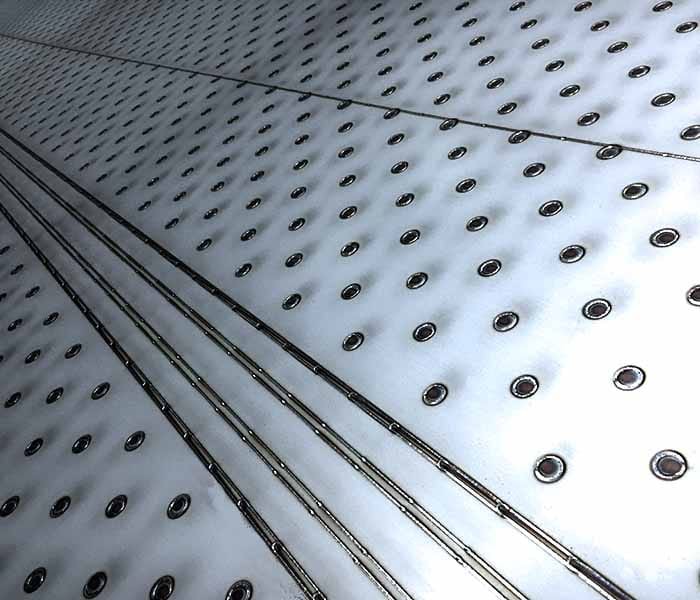

Pillow Plates Head Exchanger

Pillow Plates Pillow Plates are heat exchanger plates that can be used in many ways for the industrial cooling or heating of your products. As the developer of the laser welding machine for these Pillow Plates, HS LASER Products has an unprecedented amount of experience in manufacturing Pillow Plates. These laser welded plates have endless applications in different industries. HS LASER Pillow Plates are used for vessels, for example for cooling milk, soft drinks, wine or beer. But also various other sectors use our plates. For example, the meat processing industry, the chemical industry and the pharmaceutical industry.

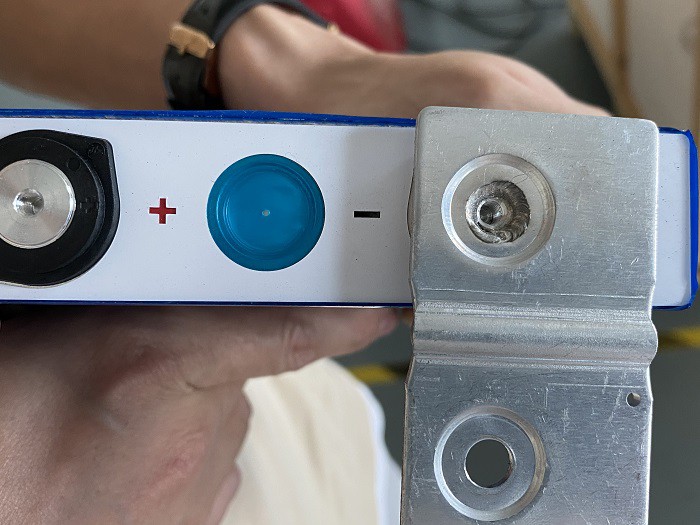

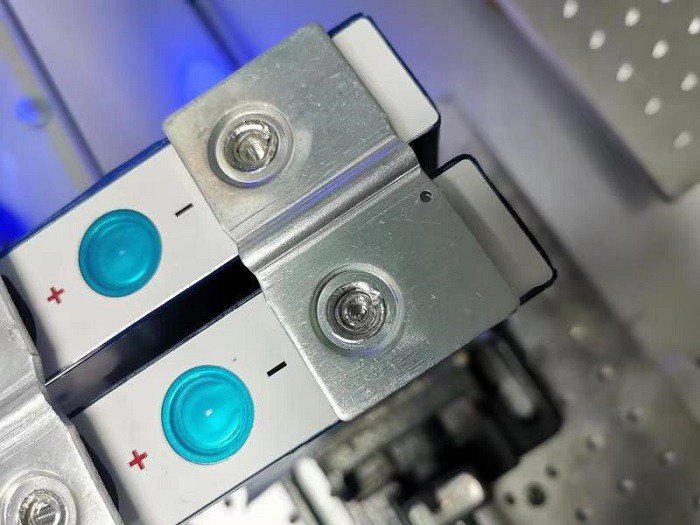

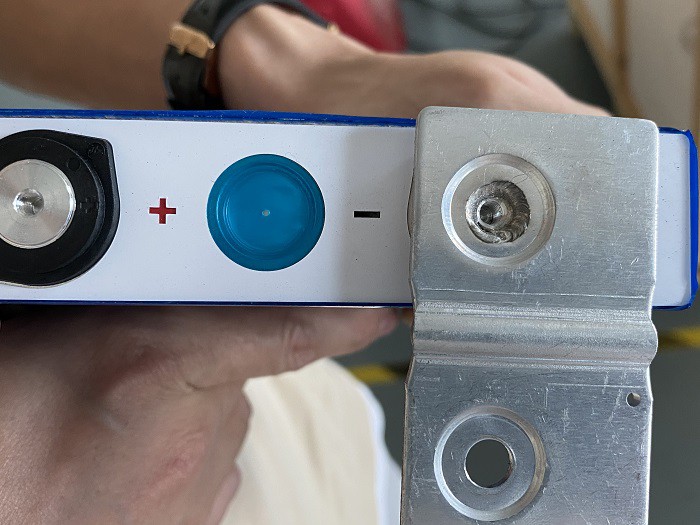

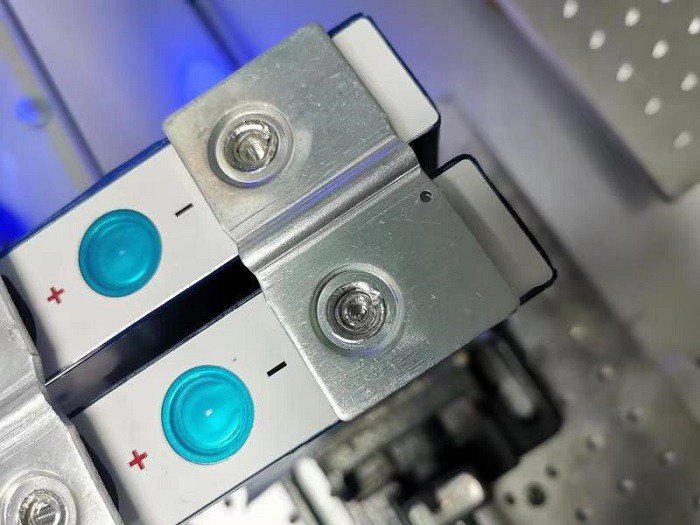

Electric Car Battery Pack Weld System

With the rapid development of the global economy, global automakers have invested in electric vehicle manufacturing, including BMW, Mercedes-Benz, Volkswagen, and Audi. Among them, Chinese brand manufacturers include the world's leading electric vehicle brands such as BYD and NIO. , Ideal one and other high-performance pure electric vehicle manufacturing. And has excellent using experinece in China.

Electric vehicles hybrid vehicles including private automobiles, transportation trucks, bikes, motorcycles, scooters and other modes of transportation driven by electrical power, all of which is provided by stored energy in batteries. on the market require lithium battery batteries to be assembled battery pack after install to electric vehichles.

This electrification – which applies across several sectors – is neatly wrapped up in new terminology: e-Mobility or Electro Mobility. According to Gartner, e-Mobility “represents the concept of using electric powertrain technologies, in-vehicle information and communications technologies and connected infrastructures to enable the electric propulsion of vehicles and fleets.” A BIG piece of the e-Mobility puzzle is battery and battery pack manufacturing.

The challenges encountered in bringing this technology to market include the demand for reduced weight, expanded range, faster charge times and lower costs. Translated into manufacturing goals, the batteries need to possess higher capacity with negligible energy loss delivering to the drivetrain, higher current carrying capacity for charging, and be made of light-weight, lower cost materials. And since the e-mobility market is so rapidly expanding, there are additional manufacturing challenges, including the demand for higher throughput and quality.

Parameters

Model number: HS-AW1000 to sm-AW6000

|

Water cooler capacity: Depend on laser power

|

Laser power: 1000W 1500W 2000W 3000W 4000W 6000W

|

Type of water: Distilled water or pure water

|

Laser type: Fiber laser technology

|

HD CCD camera: External

|

Laser wavelength: 1070-1080nm

|

Weld width range:0.5 to 5mm

|

Laser source: Raycus / IPG / Max / JPT

|

Rotary device: 80mm optional

|

Weld head: WSX / RayTools / Precitec

|

Type of gas: Argon gas / Nirogen gas

|

Motorized: Servo motor

|

Air pressure:3 to 5 bar / 0.3 to 0.5 Mpa

|

Working area: Standard 600x600mm Accept customizable

|

Power required: AC 380V±10%/50Hz 3 Ph.

|

Control system: HS LASER system

|

Total power: Depend on laser power

|

|

X axis:500mm

|

Warranty period: 24 months

|

Y axis:300mm

|

Machine dimension: 145x120x183cm

|

Z axis:500mm

|

Net Weight: 590KG

|

Fiber cable length: Standard 10m Accept costomizable

|

Package dimension:165x130x203cm

|

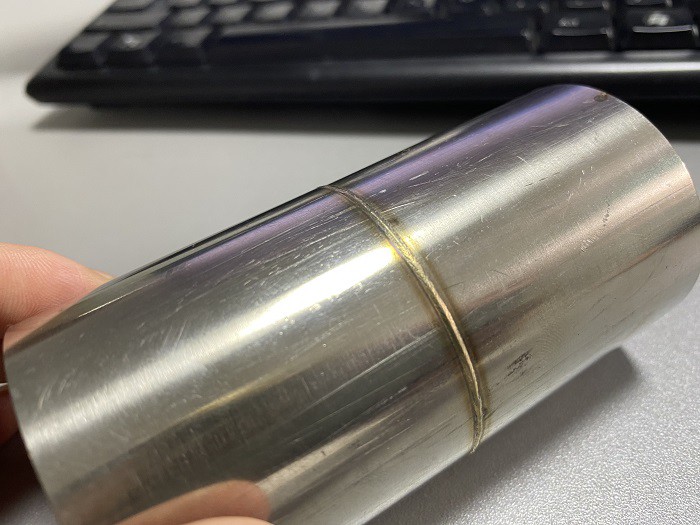

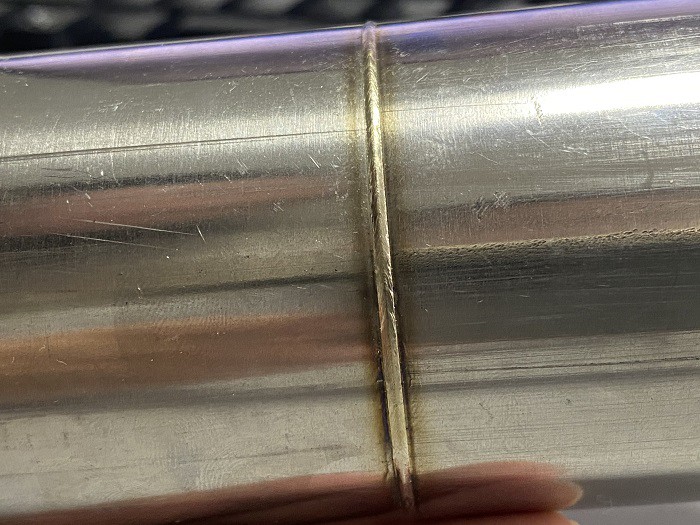

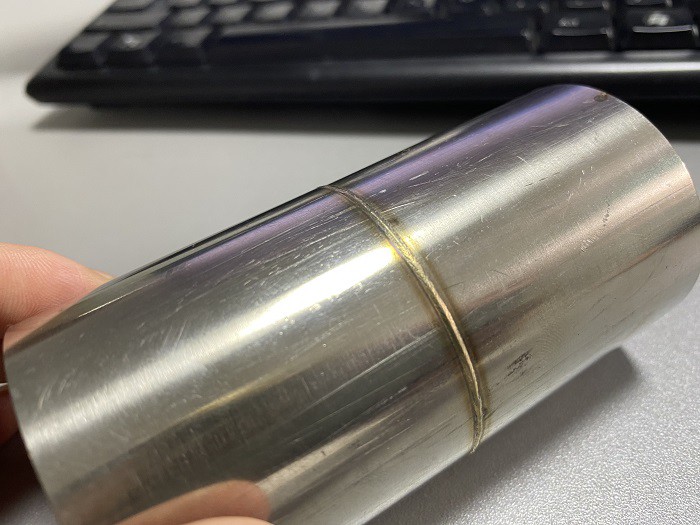

Samples

Factory Show